History

The History of Cliffe Hill

For the geologist the story of Cliffe Hill goes back 500 million years. Commercially the name granite applies to any hard stone, while geologists restrict the term to a rock consisting of three minerals Quartz, Feldspar and Mica. Cliffe Hill stone is a true Syenite, comprised of pinkish Felspar and green Hornblende.

Cliffe Hill is situated on the southern edge of Charnwood Forest and has played a part in the progress of the county, country and local community for many years. The decision to re-open the quarry in 1891 had an immediate effect on the economic scene. It provided regular employment for local men and the purchase and maintenance of plant and equipment provide work for engineering firms growing in nearby Coalville and Leicester.

Time Line

| 1870’s | Quarrying begins by Mr Jones and Mr Fitzmaurice of Birmingham |

|---|---|

| 1881 | Jones and Fitzmaurice stop working Cliffe |

| 1891 |

J.R.Fitzmaurice acquired the quarry from his father and reopens Cliffe Hill |

Mr P.Preston joins the company as manager on a salary of £3 per week. |

|

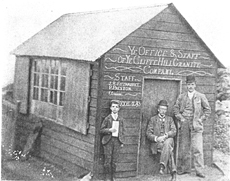

First office |

|

| 10,000 tonnes per year produced | |

| 1892 | The first major contract was secured for quarter inch clean chippings for the Patent Victoria Stone Company |

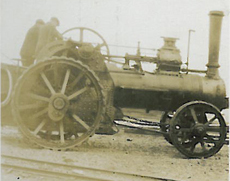

A steam traction engine was ordered and arrived in November at a cost of £469. This was used to facilitate the transportation of stone to Bagworth Station some 2.5 miles away. |

|

| 1893 | Due to the success of the previous year another steam traction engine was ordered. |

| The first large blast in excess of 1,000 tonnes of rock being brought down. Today (2011) we would expect a blast to bring down approx 20,000 tonnes | |

| 1894 | The company gained its first railway contract for 5,000 tonnes. |

| The Cliffe Hill Granite Company was formed. | |

| 1896 |

Construction of the Cliffe Hill Mineral Railway begins, with the first locomotive delivered and working by the end of the year. This was constructed due to the increased interest in the company’s products and the inadequacies of the traction engines.

Cliffe Hill Sidings

Cliffe Hill Signal Box |

| 1898 |

Office electrical plant installed to replace carbide and oil lamps.

Crushing Plant

Loading for crusher

Looking at quarry yard

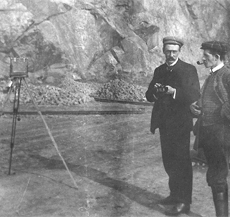

Quarry surveying |

| 1901 | Book keeper and shorthand typist employed. |

| 1902 | Installation of a concrete slab making plant. |

| 1911 | Film unit makes a promotional film of the quarry. |

| 1912 | Rockside Stone Company formed to sell non premium products. |

| 1913 |

Brick office building constructed to replace wooden shed. |

| Mr P.L.Preston joins the company as Assistant Manager. | |

| 1914 | Mineral railway track used for testing by Bagley Cars locomotive builders of Burton. |

| First articulated lorry purchased able to carry 10 tonnes and travel at 8 miles per hour. | |

| Transport garage, weigh house and weighbridge built. | |

| 1923 |

Crushing plant installed

Crushing plant |

| 1924 | Mr P. Preston retires and joins the board of directors. Mr P.L.Preston becomes quarry manager. |

| New washed plant installed to speed up the method of producing the now in demand washed aggregate. The system doubled the output | |

| Electrification of the works takes place. | |

| 1926 | Largest contract to date, 30,000 tonnes for, Leicester Corporation Sewage Works at Beaumont Leys. |

| 1927 | A new primary crusher was purchased and installed and after a seven month wait a new gyratory crusher was imported from America. |

| 1929 | Cliffe Hill sports club formed. By the summer 2 cricket and football teams existed. The company gave 2 fields for use by the club and built a pavilion. |

| 1931 | Cliffe Hill wins local area quarry methods and practice competition. |

| 1933 | A new Venture as the production of garden ornaments began but ceased only 2 years later. |

| 1934 | Cliffe Hill sports club disbanded due to a more frequent bus service to Leicester. |

| 1935 | Cliffe Hill Granite Company purchase the freehold of the quarry and surrounding property from the original founder J R Fitzmaurice |

| 1937 | A new tarmacadam plant was erected in the quarry and the old tar plant at the sidings was dismantled |

| 1938 | First electrical shovel purchased |

| 1939 | Holiday pay introduced First paid holiday taken in August 1939 |

| Entire stock of slabs sold for use in military camps. Vast amounts of material supplied for runways and ammunition factories. | |

| 1941 | The company obtained permission to use German and Italian prisoners of war their work enabled the company to continue on a reduced scale. |

| 1942 | Mr P.Preston the founder manager passed away in 1942. He served the company for 51 years, 33 as manager and 18 years on the Board of Directors. |

| 1945 | Mr Peter McHugh Preston returned from active service and took up the position of Quarry Manager, the third member of the family to serve in that capacity. |

| 1946 |

Installation of a primary crusher on the quarry floor. The rail system was replaced using road transport. The ten inch gyratory crusher was replaced by a four and quarter inch Nordberg cone crusher. Two tarmacadam plants were removed and replaced by one tarmacadam plant with increased capacity.

Aerial photo of Cliffe Hill

Truck Crane Bucket |

| 1948 | Cliffe Hill Mineral Railway Line abandoned in favour of road transport. |

| 1949 | The original founder Mr J.R. Fitzmaurice passed away |

| The company embarked on a new product (Ready Mixed Concrete). The first plant was installed at Markfield and shortly after another site was acquired in Leicester. | |

| 1950 | The company was a founder member of the British Ready Mixed Concrete Association. |

| 1953 | A large modern Asphalt plant was installed to meet increasing demand. |

| 1954 | Mr P.L. Preston passed away after serving the company for 42 years. His Son Mr Peter McHugh Preston was appointed as Managing Director |

| 1959 |

First electronically controlled batching and loading system installed to further enhance company performance.

Mayor at Cliffe Hill

Interior weigh bridge |

| 1960 |

First employee annual family day. Typical jaunts were to Skegness and London.

Annual Family Day |

| 1961 | Ready Mixed Concrete business sold. |

| Mid Norfolk Gravel company purchased. | |

| Radio Telephone communication system installed. | |

Longest serving employee Alf Swain retires after 63 years service. |

|

First edition of the “Markfieldite” issued. 14,000 copy monthly newspaper, for local villagers and employees |

|

| Black Monday flu epidemic, 31 employees have the virus and fail to attend work. | |

| 19 drivers win safe driving awards. | |

Cliffe Hill Granite used in the construction of Leicester’s first multi-storey carpark at Lee circle. |

|

| 1963 | Worse winter in 16 years saw Cliffe Hill at a stand still for a month. |

| Cliffe Hill Granite used in the construction of the local M1 section. | |

| Death of Mr P.Mc.Preston MBE at 42 years. Ending a 72 year association between Cliffe Hill Granite and the Preston Family. | |

| 1964 | The company now consists of Cliffe Hill Granite and 7 subsidiaries. |

| 1965 | The Cliffe Hill Granite company was acquired by Tarmac Roadstone |

| Major redevelopment work commences including installation of a new primary crusher. The largest in the UK at the time | |

| 1968 | Installation of an additional coating plant. |

| 1971 | 1,000,000 tonnes per annum produced. |

| 1973 | Third coating plant installed. |

| 1974 | Semi automatic loading point installed at the rail sidings allowed rapid loading of rail wagons. |

| 1978 | Further extension and landscaping of the quarry commenced. |

| 1980 | New Cliffe Hill (Stud Farm) planning application prepared. |

| 1983 | New Cliffe Hill (Stud Farm) planning application granted. |

| 1988 | New Cliffe Hill (Stud Farm) opens for business |

| 1989 | Cliffe Hill (Old) Quarry closes after 98 years. |

| 1997 | Cliffe Hill becomes part of a joint venture between Tarmac and Hanson under the banner of MQP. |

| 2002 | Primary Crusher re-sited in New Cliffe Hill and connecting conveyors installed. This exposed reserves under original Primary position and positioned for extraction at deeper levels. |

| Permission is granted to build a tunnel between New Cliffe Hill and Old Cliffe Hill. | |

| Secondary Plant Quaternary crusher type changed to increase yield of smaller size chippings required in the changing Asphalt recipes. | |

| Additional Cone crusher (XC10) installed and secondary crusher bypass “Grizzly Feeder” installed to increase Secondary Plant feed rate. | |

| Cornish Miners commence work on the tunnel from Old Cliffe Hill. | |

| 2003 | Australian miners commence work on the tunnel from New Cliffe Hill. |

|

Tunnel break through and official opening.

Tunnel Engineers with Plaque

Tunnel with dumper |

|

| M.O.T. (Type 1) production and stock out facility added to Primary Production Route. Previously this product was blended from Secondary processed aggregate. | |

| 2004 | Scalpings Wash Plant built in response to increasing Scalpings Stocks resulting from the 2002 introduction of the “Aggregates Levy. |

| 2005 | Resumption of production at old Cliffe Hill after lying dormant for 16 years. |

| 2006 | The Quarry’s dated ‘GEM 80’ hard wired control system completely replaced by a PC based ‘Allen Bradley” Scada system and “Fibre-optic” network. |

| Quarrying ceased at New Cliffe Hill. | |

| 2007 - 2009 | Focus was on the construction of Wednesbury Asphalt Plant and the evacuation from Edwin Richards Quarry including the demolition. |

| 2009 | Demolition of Screening Plant and associated Conveyors at Whitwick Quarry. |

| Complete replacement of aging control system on both the Marini and Quadratech Asphalt Plants. | |

| 2010 | Installation of conveyors, associated hoppers and feeders along with storage sheds for the introduction of RAP to the Marini and Quadratech Asphalt Plants. |

| Load & Haul Contract returns to an "In House" operation. | |

| 2011 | Construction of Storage to provide the weather protection of imported sands to minimise moisture content thus maximise energy efficiency. |

| 2012 | MQP pass 2 million man hours without a lost-time incident (LTI) at Cliffe Hill Quarry. |

| The Competition Commission (CC) stipulates that Tarmac must sell its share in MQP because of the proposed JV between Anglo American/Tarmac and Lafarge. | |

| 2013 | Hanson takes full ownership of MQP. |

| 2014 | In June Clee Hill Quarry and Asphalt Plant, Shropshire is added to the MQP network of units. |

| In October Baston Fen, Lincs and Northampton Asphalt plants become part of MQP. | |

| 2015 |

The primary Crusher was moved 700m, after 2 years of planning, to a new location within Old Cliffe Hill Quarry. |

| St Ives, Cambs Asphalt Plant is reopened to become part of MQP. |